Hey everyone, I’m trying to get some help with some ideas and best mods. I’m currently on my third deployed to Iraq and I’m having Bent Metal Customs in Washington swap my engine over to the 4BTA. I’m hoping when I head home my truck will be finished. Over the next month and a half I will be updating this thread with the progress Bent Metal Customs makes.

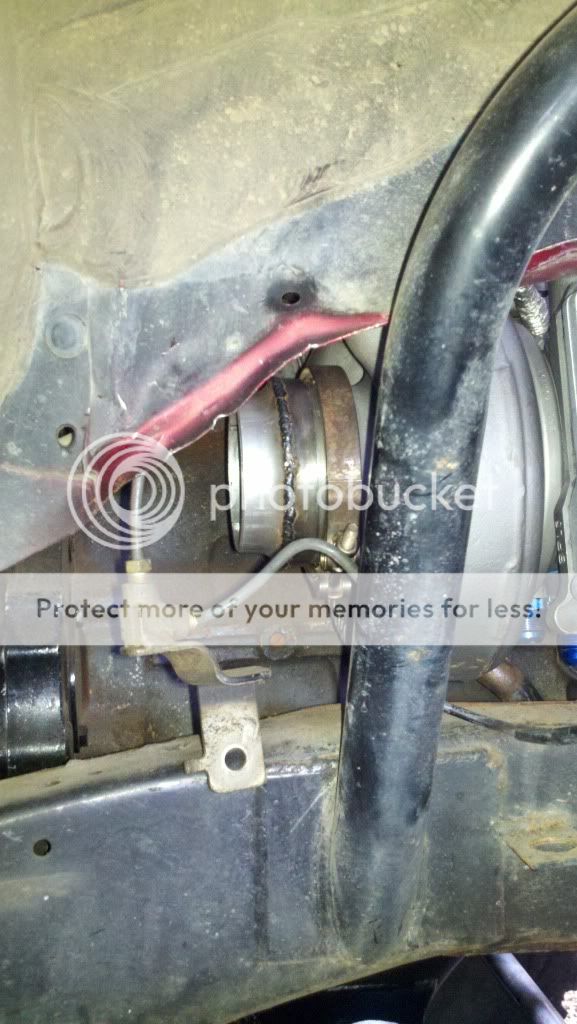

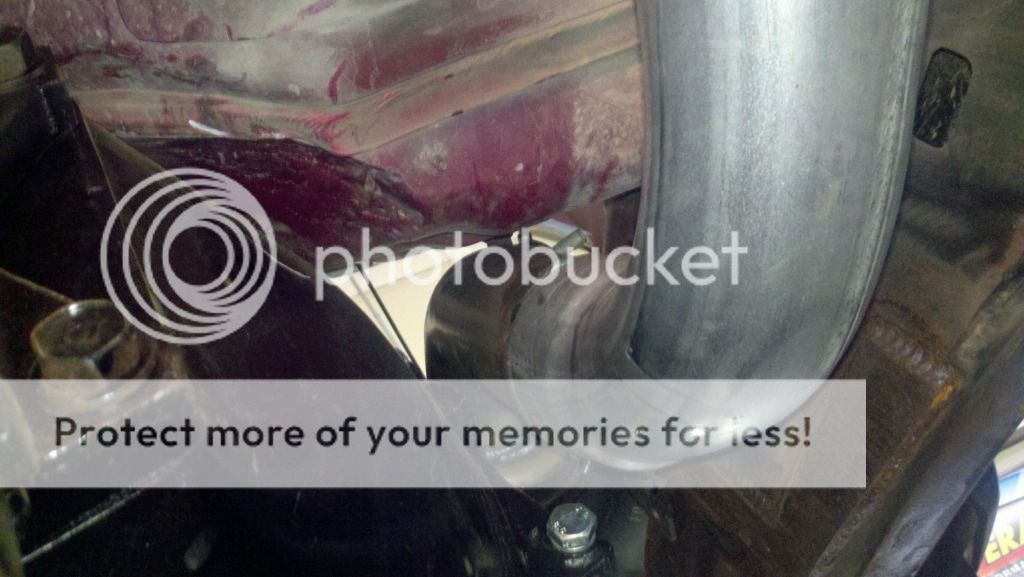

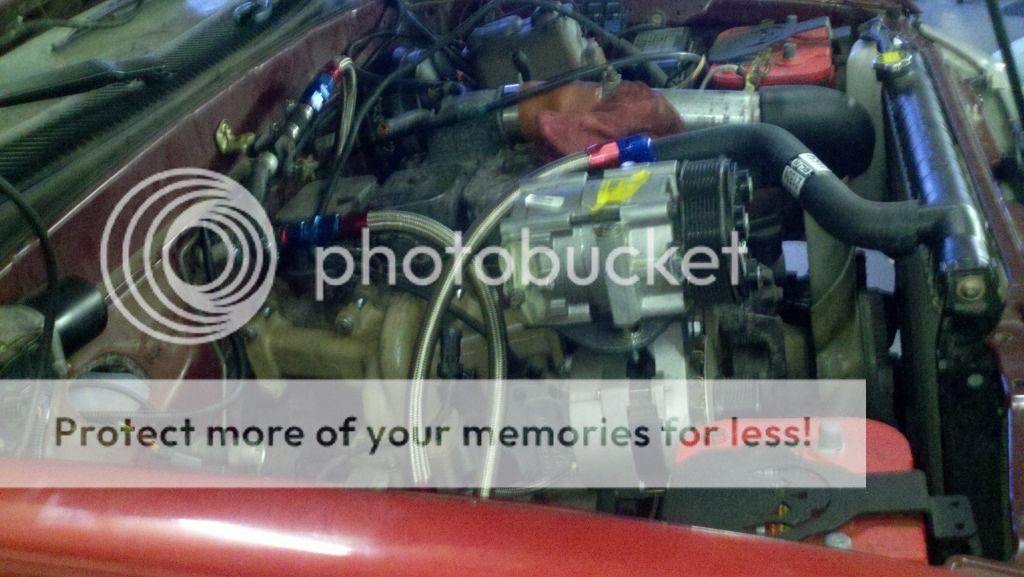

The engine I bought is a 2005 4BTA 130HP CPL 1839, I’m planning on using a Dodge Getrag 360 I bought off Ebay with a Ford NP205.

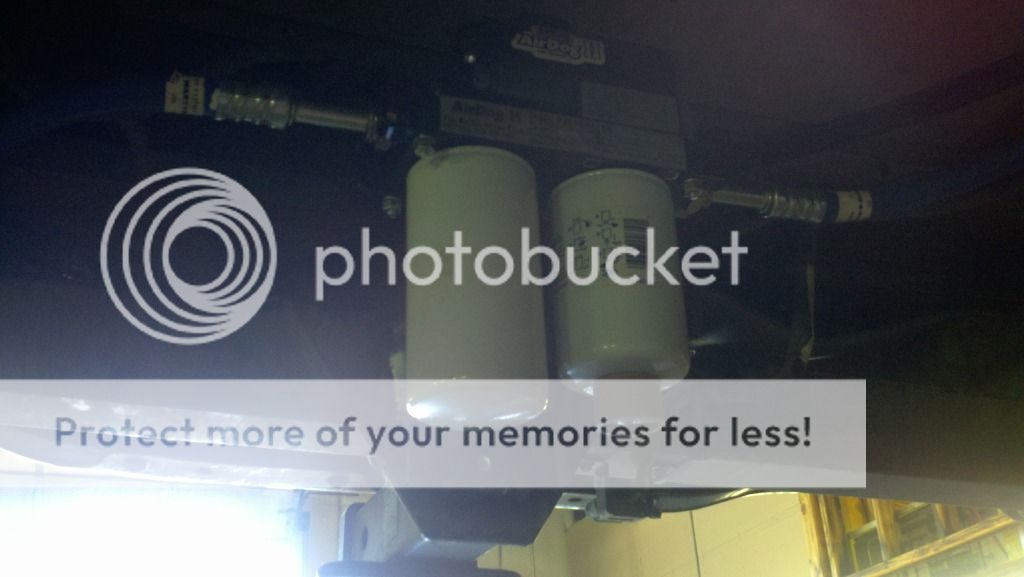

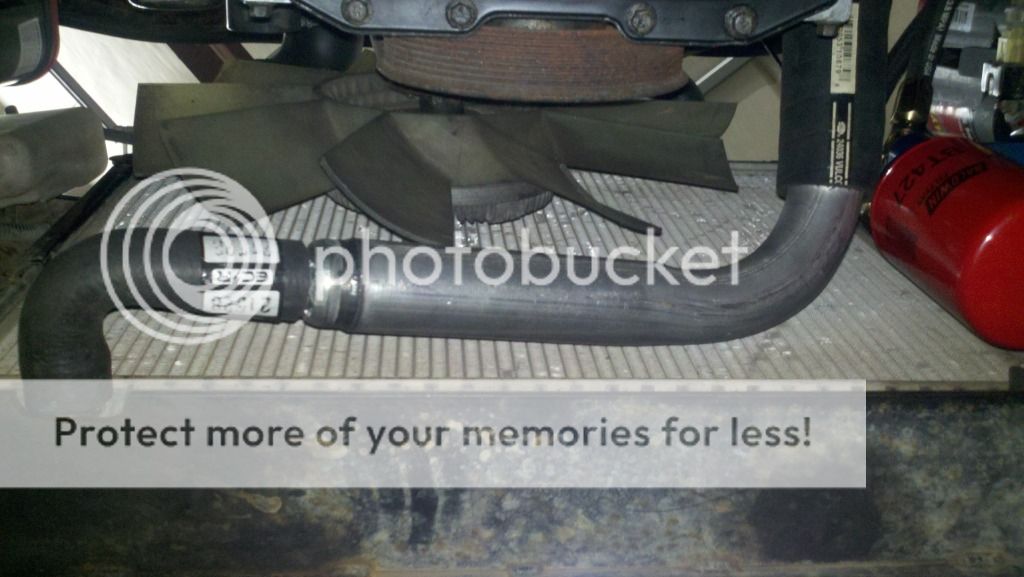

My plan is to get feedback from you guys on the site for ideas on best gauges, axle ratio, fan setups, vacuum for power steering, air conditioning, governor spring, top mount intercooler heater hoses. Ect

The engine I bought is a 2005 4BTA 130HP CPL 1839, I’m planning on using a Dodge Getrag 360 I bought off Ebay with a Ford NP205.

My plan is to get feedback from you guys on the site for ideas on best gauges, axle ratio, fan setups, vacuum for power steering, air conditioning, governor spring, top mount intercooler heater hoses. Ect