It has begun. Project Vehicle is a 2004 Dodge Durango SLT 4x4. It has 92,000 miles and a siezed hemi. Hemi-ectomy is underway. The current plan is to use a 47RH or RE with a 4bt and the existing transfer case.

I still need to purchase the transmission, electric vacuum pump

intercooler, otherwise all hard parts are acquired. I have numerous 6bt parts from a 53 block removed from my 99 Ram so i plan to set up the front of the engine similar to the dodge 6bt, dodge alternator, belt routing and ac compressor location etc.

Next steps:

Hemi-ectomy - there is very little room around bell housing, a real challenge to remove, plus engine is siezed so i am going to attempt to leave TC on engine when i pull since i can't spin crank to separate flex plate from TC, could be messy.

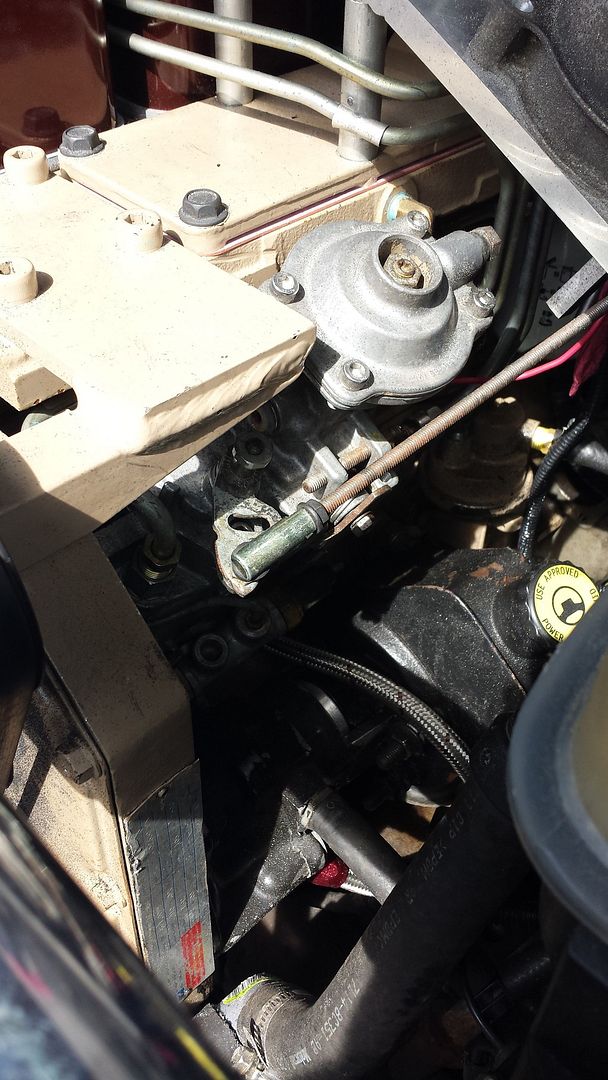

Motor mounts - have 6bt mounts, not sure if they will be part of the solution or not, current hemi mounts to the frame and IFS mount seem simple and could be part of the solution too.

Oil pan - plan to make a 4bt/hemi oil pan hybrid, space between front diff and pan is tight

Intercooler install - not sure what intercooler to use, or where it will be located exactly, i am sure i will be inspired at the time

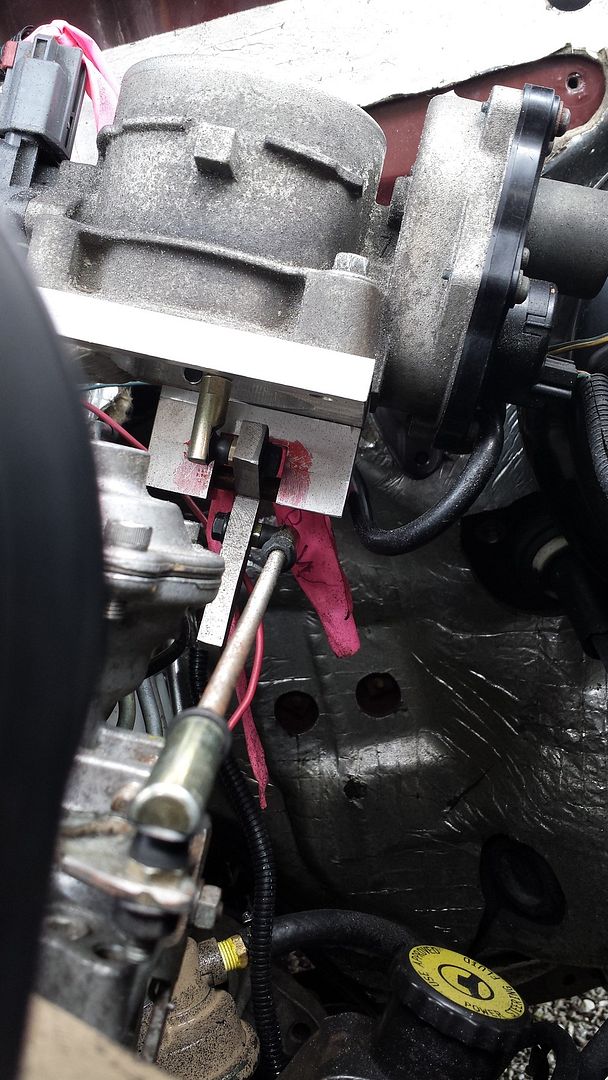

Tachometer - plan to use hemi crank sensor and mount tone ring on damper, not sure if i will need cam sensor or not

Temp sensor - hemi temp sensor mounted in 4bt

Oil pressure switch - hemi oil pressure switch

I still need to purchase the transmission, electric vacuum pump

intercooler, otherwise all hard parts are acquired. I have numerous 6bt parts from a 53 block removed from my 99 Ram so i plan to set up the front of the engine similar to the dodge 6bt, dodge alternator, belt routing and ac compressor location etc.

Next steps:

Hemi-ectomy - there is very little room around bell housing, a real challenge to remove, plus engine is siezed so i am going to attempt to leave TC on engine when i pull since i can't spin crank to separate flex plate from TC, could be messy.

Motor mounts - have 6bt mounts, not sure if they will be part of the solution or not, current hemi mounts to the frame and IFS mount seem simple and could be part of the solution too.

Oil pan - plan to make a 4bt/hemi oil pan hybrid, space between front diff and pan is tight

Intercooler install - not sure what intercooler to use, or where it will be located exactly, i am sure i will be inspired at the time

Tachometer - plan to use hemi crank sensor and mount tone ring on damper, not sure if i will need cam sensor or not

Temp sensor - hemi temp sensor mounted in 4bt

Oil pressure switch - hemi oil pressure switch