hello all, early this summer i aquired a wrecked 1990 w250 non i/c ctd getrag 205 truck with the intentions of a cummins powered chevy. in july while working on the road,(construction) i came across a pair of old 4x4 chevy pickups sitting in a guys yard that looked as if they had been neglected for some time. one was a rotted out 78 1ton and the other a salvagable 85 3/4 ton with the fancy 89 grille and headlamps.

![Image]()

after knocking on the guys door i decided the price was right and found a way to get these bad boys home 250 miles away.

got them home and started tearing into the 85. I stripped it down to the bare frame and running gear, and got the frame cleaned up and undercoated. after further reveiw, i decided the cab floor was too far gone to fix. i got on craigslist and scored a better 82 cab for a decent price that needed just a pass side floor pan opposed to the entire floor. after the underside of the cab was prepped and undercoated on the frame it went.

![Image]()

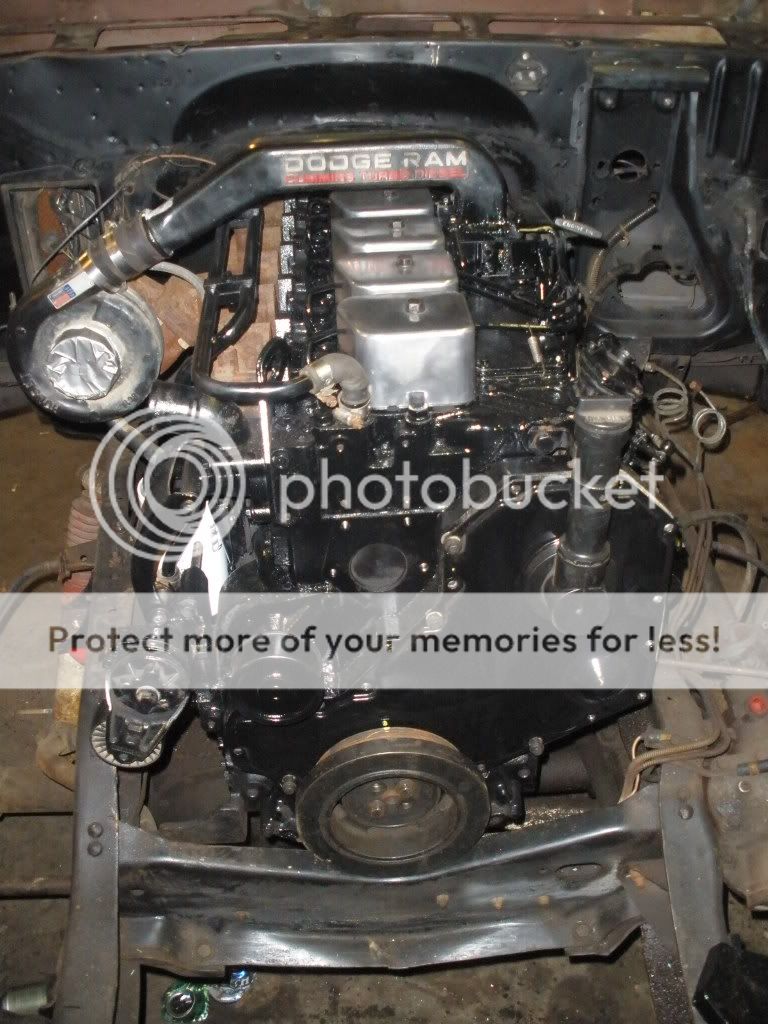

got the cummins pulled from the donor and noticed a hole in the timing case beside the vac/ ps pump. turned out the vacuum pump bearing shelled and dropped the gear into the cam and injection gears. i replace the timing housing, cam and injection gears, oil pump (scored badly from debris) and got a new p-30 style pump setup thanks to jakey on here for sourcing the parts.

![Image]()

after getting it all buttoned back up in she went using the mopar 1st gen mounts i modified.

![Image]()

heres as it sits right now, ill be updating this thread as i go

![Image]()

after knocking on the guys door i decided the price was right and found a way to get these bad boys home 250 miles away.

got them home and started tearing into the 85. I stripped it down to the bare frame and running gear, and got the frame cleaned up and undercoated. after further reveiw, i decided the cab floor was too far gone to fix. i got on craigslist and scored a better 82 cab for a decent price that needed just a pass side floor pan opposed to the entire floor. after the underside of the cab was prepped and undercoated on the frame it went.

got the cummins pulled from the donor and noticed a hole in the timing case beside the vac/ ps pump. turned out the vacuum pump bearing shelled and dropped the gear into the cam and injection gears. i replace the timing housing, cam and injection gears, oil pump (scored badly from debris) and got a new p-30 style pump setup thanks to jakey on here for sourcing the parts.

after getting it all buttoned back up in she went using the mopar 1st gen mounts i modified.

heres as it sits right now, ill be updating this thread as i go