The 1995 12v 160hp engine made it here from California this am! Picked it up from a guy who swapped it out for a 24v and 5sp...because he needed "more power" Um..OK...that is what a fuel plate is for...oh well.

180K and the only "leaks" I can see are around the valve covers and some down by the PS pump.

I have looked and studied and looked some more over the years at these things...and to finally see a 12v in person ( I had an 06 common rail for 2 years) is amazing...soooooo simple.

Now I need to order the swap kit from here and start picking up a few other things. Need a starter / ac pump / idler pulley / intercooler / alternator / dipstick.

Here are a few pics of the engine...this first is of the "wrong hose" being used between the fuel heater and the lift pump. ( I thought I could "link" but my post count is not high enough yet...so here they are in who knows what order)

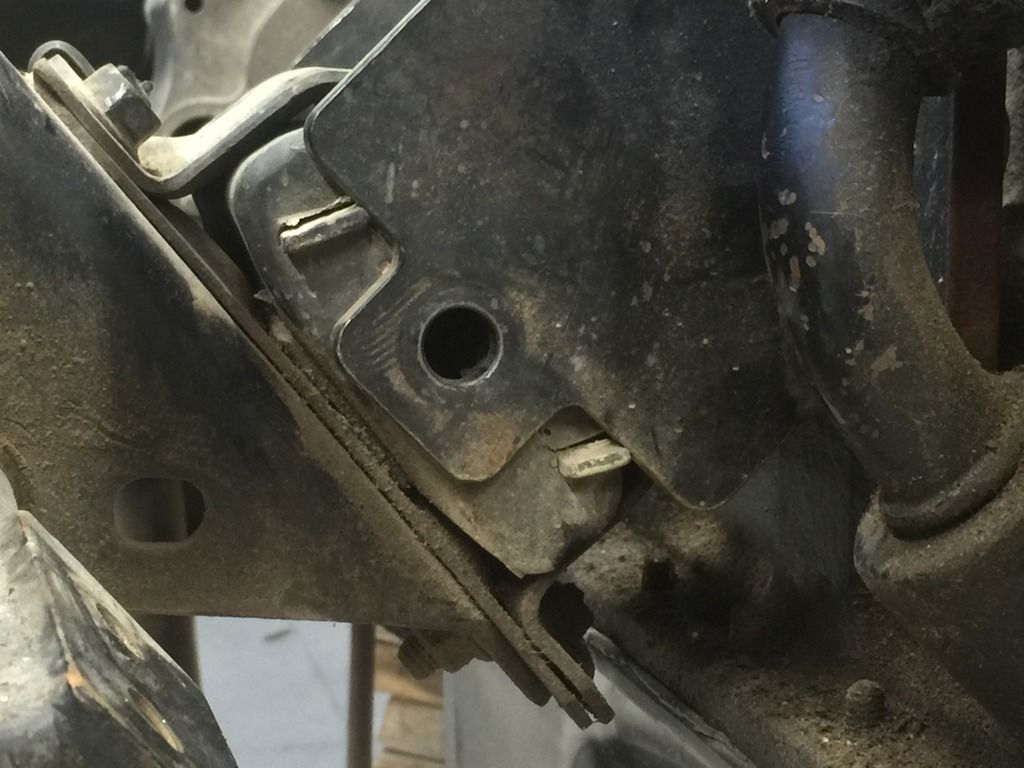

Next is of the booger welded throttle linkage....BTW...the fuel shut off solenoid boot is torn too.

Here is a pic of the truck as well.

OK...enough posting...back to the garage to admire my "New baby" ha ha ha and make a parts list for Tuesday mornings "parts call"

180K and the only "leaks" I can see are around the valve covers and some down by the PS pump.

I have looked and studied and looked some more over the years at these things...and to finally see a 12v in person ( I had an 06 common rail for 2 years) is amazing...soooooo simple.

Now I need to order the swap kit from here and start picking up a few other things. Need a starter / ac pump / idler pulley / intercooler / alternator / dipstick.

Here are a few pics of the engine...this first is of the "wrong hose" being used between the fuel heater and the lift pump. ( I thought I could "link" but my post count is not high enough yet...so here they are in who knows what order)

Next is of the booger welded throttle linkage....BTW...the fuel shut off solenoid boot is torn too.

Here is a pic of the truck as well.

OK...enough posting...back to the garage to admire my "New baby" ha ha ha and make a parts list for Tuesday mornings "parts call"